Induction Furnace Melting Process and Quality Control

Target Audience: Metallurgical Engineers, Melting Supervisors, QA/QC Engineers 1. Charge Material is Everything: Pre-treatment &

Target Audience: Metallurgical Engineers, Melting Supervisors, QA/QC Engineers 1. Charge Material is Everything: Pre-treatment &

1. Automotive Engine Block Casting: Stability Control in Mass Production of Gray Cast Iron In

When it comes to purchasing and operating induction furnaces, we often hear too much “old

This is a highly specialized subject that addresses the core pain points of casting and

1. War in the Micro-World: Identification and Traceability of Endogenous vs. Exogenous Inclusions in Induction

Induction furnaces are notorious “troublemakers” in industrial power grids. As typical non-linear loads, balancing melting

In foundry production, although Slag Coagulants (or Slag Removers) make up a small percentage of

Topic 1: The Meniscus Effect How it impacts slag removal and lining life. When an

The Capping (Top Cap) and Spout (Runner) are the areas requiring the most frequent maintenance.

In induction furnace melting, the choice of recarburizer directly dictates the metallurgical quality of the

This is a highly specialized topic that lies at the core of modern micro- at

In an induction melting environment, operators face the dual threats of extreme temperatures (high infrared/ultraviolet

In the installation of refractories (especially induction furnace linings), Pneumatic Rammers and Electric Vibrators are

In the foundry, there is a common saying: “30% Installation, 70% Sintering.” If building the

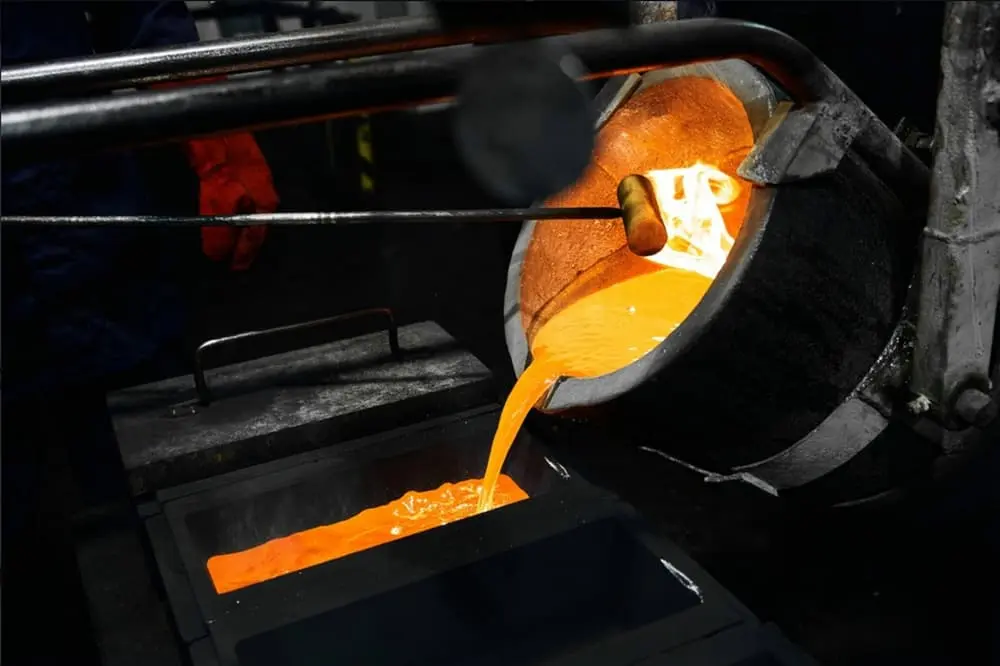

In the induction melting process for non-ferrous metals (specifically Copper, Aluminum, Gold, and Silver), ang

Content Focus: Specifically for pure copper (red copper) pagtunaw ng mga. This guide discusses the susceptibility of

Content Focus: During a total plant blackout, the molten iron within the furnace continues to

For the melting of non-ferrous and precious metals like Copper, Aluminum, Gold, and Silver, ang

Compared to Electric Arc Furnaces (EAF), the Waste Heat Recovery (WHR) profile of an Induction

In the foundry and metallurgy industries, scrap metal typically accounts for 60% sa 70% of

Content Focus: Exploring how to build a closed-loop quality control system. Once the spectrometer analyzes

In the automotive industry, the casting of engine blocks (typically HT250/GJL-250 or HT300/GJL-300 grade Grey

Target Industry: Wind Power (specifically large castings like hubs, bedplates, and bearing housings). Focus: Challenges

Using casting defects to “reverse engineer” melting problems is a highly effective quality diagnosis method.

When evaluating an investment in an induction furnace, enterprises that focus only on the equipment’s

In modern foundry and metallurgy, the induction furnace is favored for its high efficiency, cleanliness,

This is a very important and practical issue. Induction furnaces are major energy consumers in

Here is “The Ultimate Guide to Safe Induction Furnace Operation: 10 Golden Rules,” meticulously compiled

Modern foundries are increasingly favoring induction furnaces primarily because they offer significant advantages in improving

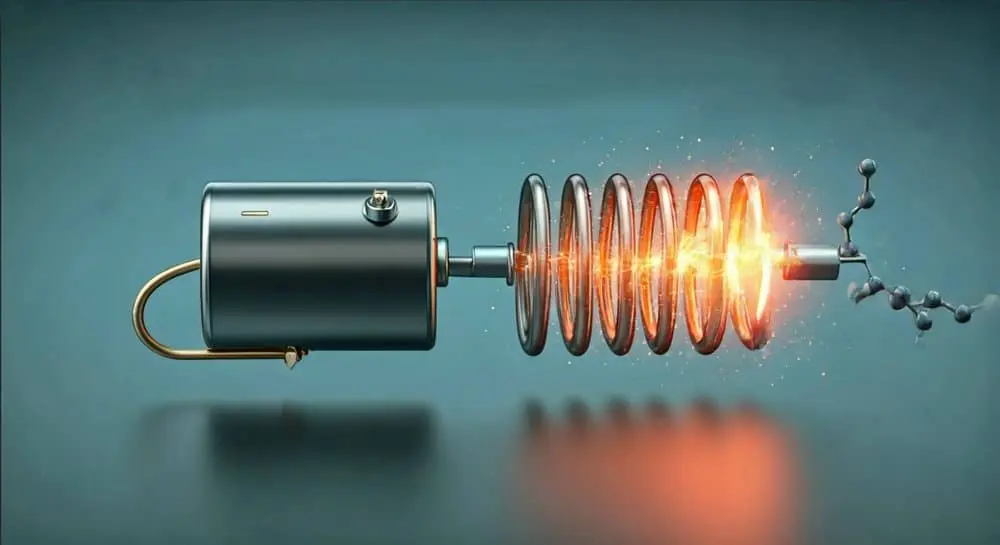

When Induction Heating is mentioned, you might first think of the massive furnaces in factories

This is a detailed introduction to the core components and functions of a Medium Frequency

Welcome to the world of induction furnaces. Simply put, an induction furnace is an electrical

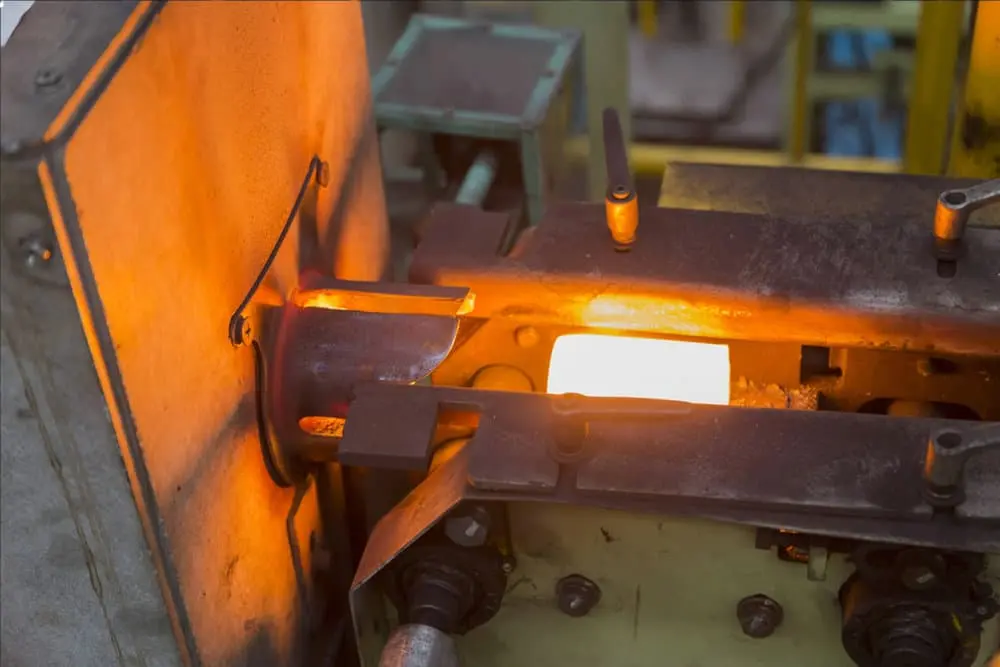

The impact of automatic feeding systems (especially vibratory and electromagnetic types) on melting efficiency is

In the modern foundry industry, induction furnaces are widely used due to their high efficiency,

From a physical metallurgy viewpoint, this article delves into the dissolution mechanisms and diffusion rates

In induction melting technology, the seemingly calm liquid metal in the molten bath is, in

Executive Summary: In foundry production, scrap steel is an indispensable furnace charge material, but its

During the induction furnace melting process, inclusions are a critical factor affecting the final quality

In the realm of metal melting, induction furnaces, electric arc furnaces, and cupola furnaces are

Purchasing an induction furnace is more than a simple equipment acquisition; it is a long-term

Purchasing an induction furnace involves far more than just the initial equipment price. When making

In the field of metal smelting, especially when using induction furnaces, the phrase “the charge

Induction furnaces generate significant amounts of dust and fumes during the melting process, which not

Induction furnaces use powerful, alternating electromagnetic fields to rapidly heat metals, making them highly efficient

In the field of modern industrial thermal processing, the induction furnace plays an indispensable role

In the high-temperature, high-pressure, and high-risk environment of a casting workshop, every furnace ignition is

A deep technical comparison of two mainstream power supply topologies, analyzing their differences in power

In the industrial melting sector, the configuration of electric furnaces is critically important for production

“The Alarm Will Go Off Anyway”: Debunking 5 Fatal Safety Misconceptions in Induction Furnace Operation

A common misconception exists among many industrial furnace operators: as long as the furnace lining

The Induction Furnace Isn’t a Universal Melter, Revealing Its Limitations with Certain Materials. With its

In the field of induction melting, a common misconception is that infinitely increasing the power

When “induction heating” is mentioned, many people might picture massive industrial furnaces and scenes of

Induction furnaces are widely used in foundries and for special steel production due to their

In the modern field of metal melting and holding, coreless and cored induction furnaces stand

As a highly efficient and clean metal smelting technology, the induction furnace plays a vital

In the metal smelting process, deslagging (slag removal) is a critically important yet highly challenging

As the core of modern industrial heating, the development of induction heating power supply technology

In industrial production, the induction furnace is a key piece of equipment for melting metal,

Step into a modern foundry, and you might expect to see a fiery, smoky, “Bakal na Bakal

Narito kami para sa iyong mga katanungan anumang oras 24/7, Maligayang pagdating sa iyong konsultasyon.

Karapatang-ari © 2025 ShenGuang. Lahat ng karapatan ay nakalaan.