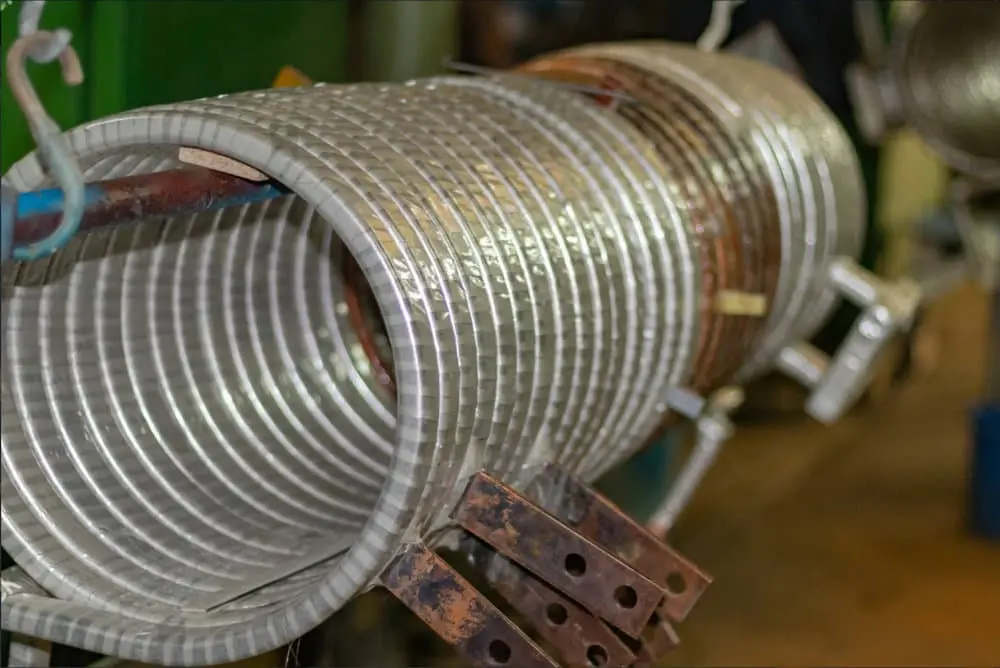

Induction Coil Design and Optimization

Induction heating, as a highly efficient, malinis na, and controllable heating method, plays a vital role

Induction heating, as a highly efficient, malinis na, and controllable heating method, plays a vital role

Due to its high efficiency, speed, and controllability, induction heating is widely used in applications

Mga hurno ng induction, as an advanced heating technology, play a pivotal role in achieving sustainable development

Induction furnaces play a pivotal role in modern automotive manufacturing, with applications spanning from core

Different countries have developed unique characteristics and advantages in induction furnace technology. Here’s a comparison

As the world accelerates towards a cleaner, more sustainable energy structure, new energy technologies are

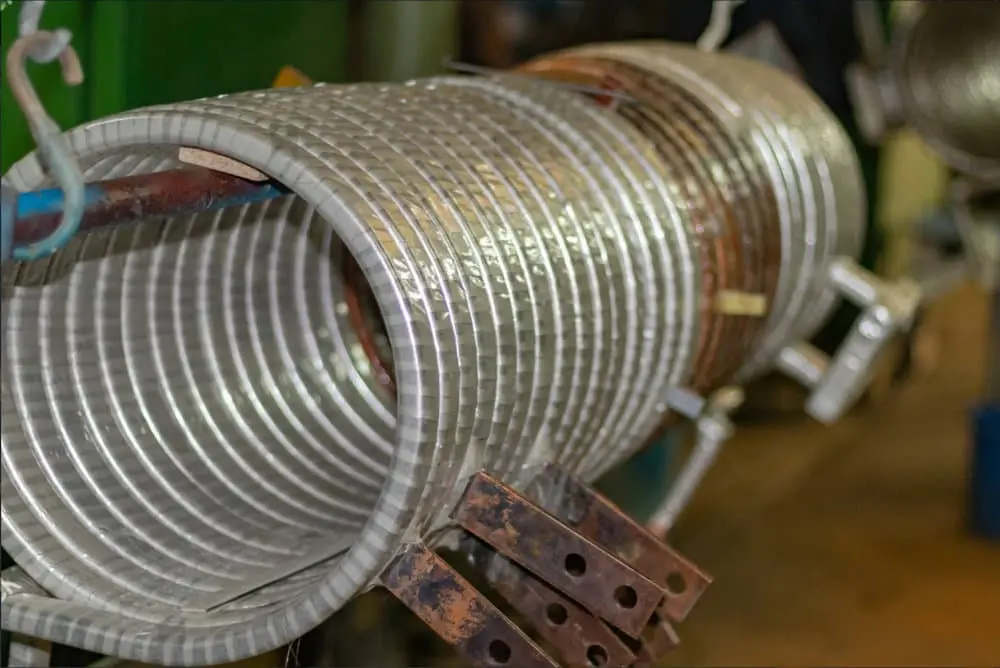

The cooling system is critical for induction furnaces, as they generate significant heat during operation.

Induction melting technology, with its unique advantages, is revolutionizing the traditional metal melting and casting

Multi frequency induction heating technology is an advanced method that uses a combination of different

The proper installation and commissioning of a induction furnace are crucial for its operational lifespan,

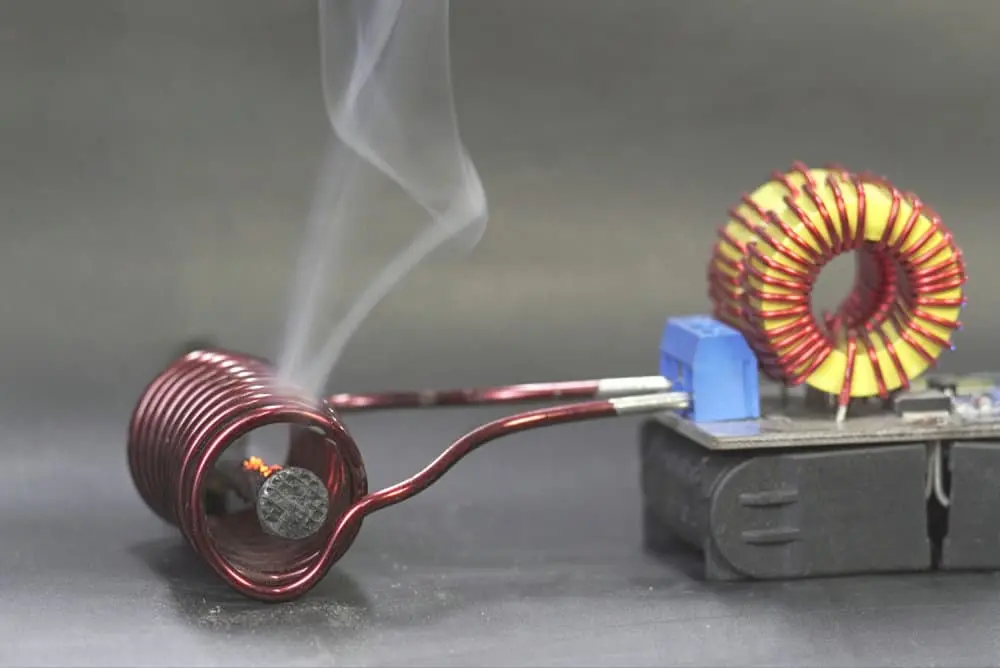

An induction heating furnace is a device that uses the principle of electromagnetic induction to

In industrial production, especially in high-energy-consuming and high-emission industries like casting and metallurgy, the energy-saving

The structure design of the induction furnace is the key to its performance and safety.

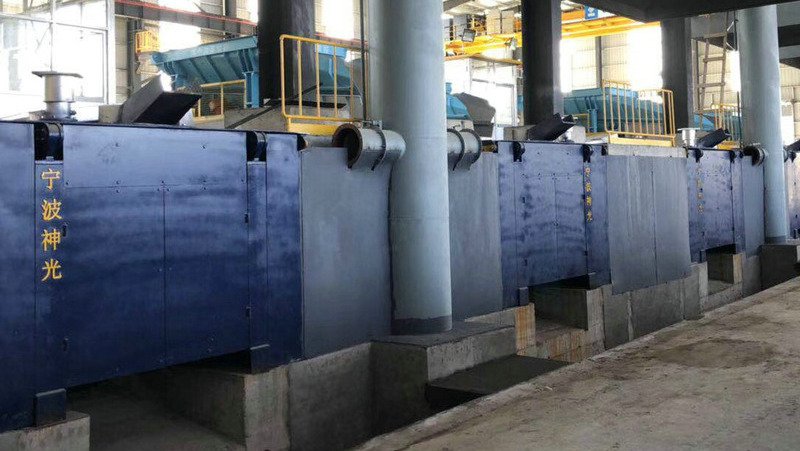

Welcoming the Future of Metal Melting: Shenguang Electric Furnace Invites You to Discuss New Chapters

With the increasing demands of industrial production for melting efficiency and capacity, high power induction

Rapid solidification processing (RSP) is a technology that uses extremely high cooling rates (usually 103

We often think of metal melting as a fiery, open-air process. While that image holds

The working principle of the induction furnace is electromagnetic induction heating. So what is the

Induction furnaces are a cornerstone of the modern foundry industry, offering a clean, efficient, at

In the relentless flow of modern industry, the melting and heating of metals play a

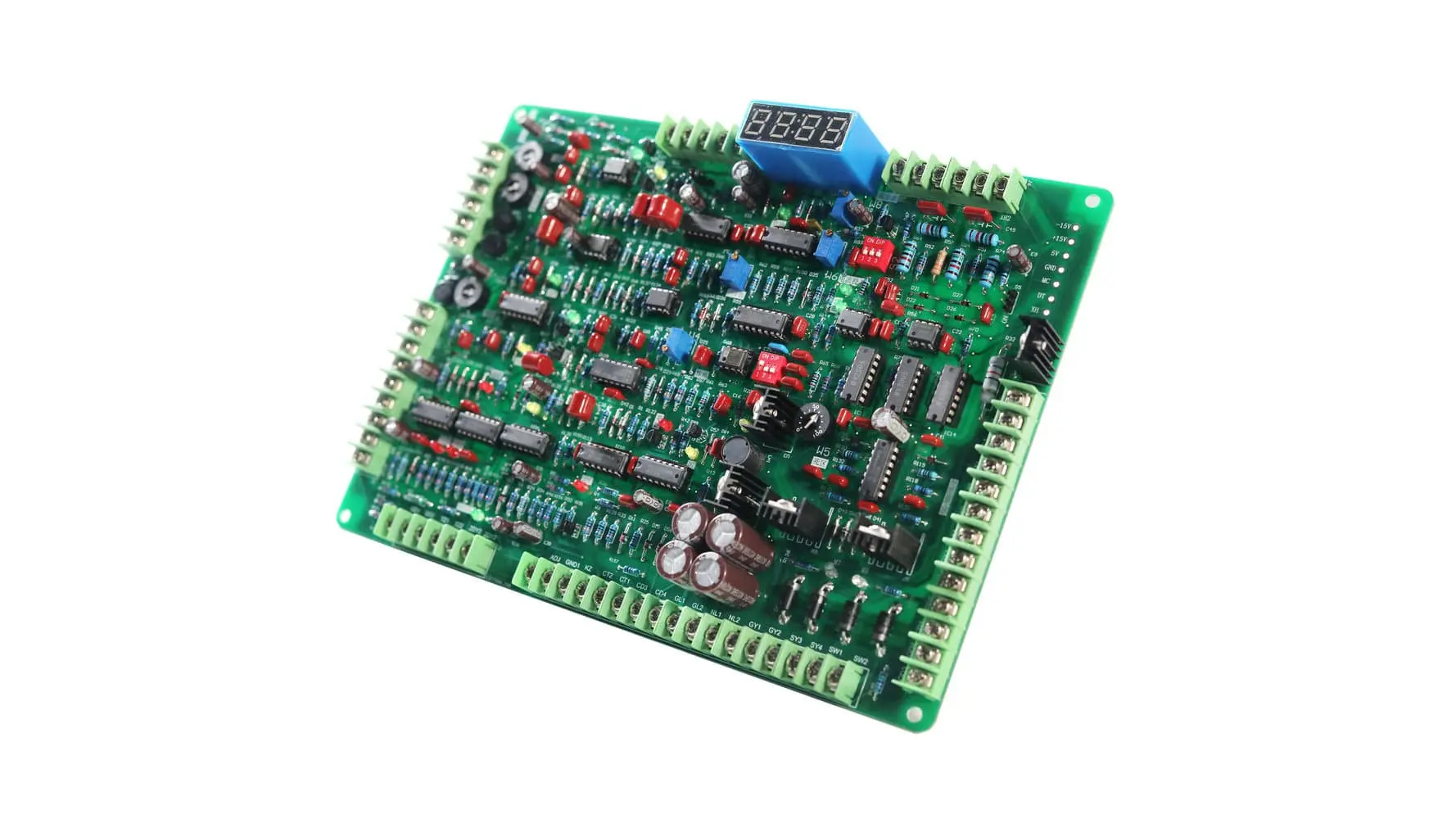

Induction furnace control systems play a vital role in modern industrial production. They are widely

In the application of induction furnaces, sensors and flowmeters are key components to ensure efficient,

Hydraulic systems play a crucial and indispensable role in the design and operation of induction

The induction furnace generates a significant amount of heat during operation. If this heat is

Mga hurno ng induction, Mahalagang kagamitan sa pag-init sa modernong industriya, Malawakang ginagamit sa pagtunaw ng metal,

Induction furnaces play a crucial role in modern metallurgical industries, and refractory materials, as their

As a key equipment for modern industrial production, the steady development of the industrial chain

Aluminum alloy, as a lightweight, high-strength, and corrosion-resistant metal material, plays a vital role in

In modern industry, the demand for high-performance materials is growing, especially in critical sectors such

Electric Vehicles’ Demand for Lightweight Metals The lightweight design of electric vehicles (EVs) is key

Ang pagsusuri ng mga mapagkumpitensya na kalamangan sa medium frequency furnace market ay nagsasangkot ng maraming aspeto, which

Ang mga medium frequency indcution furnaces ay gumaganap ng isang mahalagang papel sa industriya ng paggamot ng init, with a

Sa modernong produksyong industriyal, pagkukubli, bilang isang mahalagang metal processing technique, is widely used in

Mga hurno ng induction, as essential thermal processing equipment in modern industry, are evolving in close alignment

Mga hurno ng induction, with their advantages of high efficiency, Pag-save ng Enerhiya, and easy control, occupy an

An induction furnace is a device that utilizes medium-frequency current for induction heating, widely used

Choosing the right induction furnace is crucial for optimizing your production processes. Several factors must

Ang mga pugon ng Induction ay naging napakahalaga sa mga modernong proseso ng industriya, partikular na sa metal melting at init

Habang alumina powder ay hindi ganap na hindi tugma sa mga pugon ng induction, ang tuwirang paggamit nito ay nagtatanghal ng makabuluhang

Pagdating sa pagtunaw ng aluminyo pulbos para sa paghahagis o haluang metal produksyon, ang pagpili ng

Ang pagtunaw ng induction ay isang malawak na ginagamit na proseso sa industriya ng bakal para sa paggawa ng mataas na kalidad na mga ingots.

Ang medium frequency induction furnace ay isang uri ng electric furnace na ginagamit para sa pagtunaw ng mga metal, partikular na ang

bakal na bakal, kilala sa lakas nito, tibay ng katawan, at maraming nalalaman, ay nasa ubod ng hindi mabilang na mga industriya,

Ang paglalagay ng riser ay mahalaga para sa pagtiyak ng kalidad at integridad ng mga castings. Properly positioned risers

The Induction furnace is a crucial piece of equipment in the metal melting industry, offering

Iron melting is a fundamental process in metalworking and foundry industries, playing a crucial role

Ang mga kagamitan sa pagtunaw ng induction ay naging isang batong panulok sa industriya ng metalworking at foundry. This technology

When working with metals and alloys, terms like “pagtunaw ng mga” at “natutunaw na” often come up, but

Ang pagtunaw ng tanso ay nagsasangkot ng pagkuha ng tanso mula sa mga ores nito, Pangunahin sa pamamagitan ng dalawang pamamaraan: pyrometalurhiya

Vacuum furnaces and induction furnaces are both widely used in heat treatment processes, but they

A crucible melting furnace is an essential tool in foundries, primarily used for melting metals,

1. Design and Working Principle 2. Kapasidad 3. Saklaw ng Dalas 4. Energy Efficiency 5. Natutunaw na

Induction furnaces come in several types, primarily categorized based on their design, function, and application.

When selecting a furnace for melting copper and its alloys, the choice often comes down

The division of metals into ferrous and non-ferrous categories is based primarily on their iron

The working principle of an Induction Copper Melting Furnace revolves around the use of electromagnetic

The main requirements of a heat treatment furnace depend on the specific heat treatment process

Pagdating sa metal natutunaw, ang pagpili ng pugon lining materyal ay gumaganap ng isang kritikal na

Ang pagpepresyo para sa mga pugon ng induction ay maaaring mag iba nang malaki batay sa laki, Paglalapat, at pagsasaayos. Maliit na Sukat

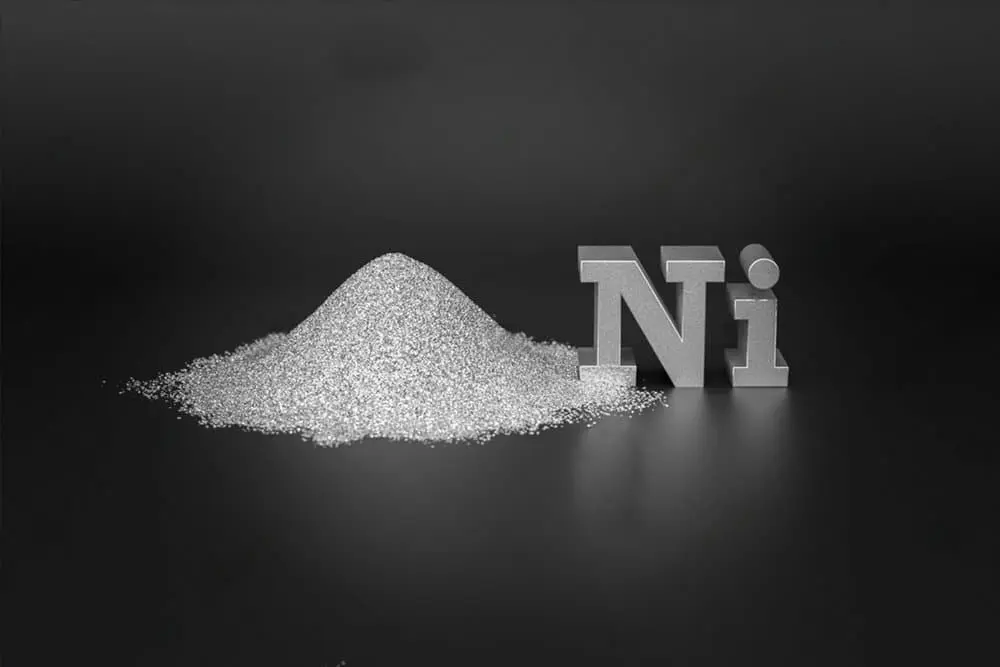

Ang pagdaragdag ng nikel sa panahon ng proseso ng pagtunaw ng bakal ay makabuluhang nagpapahusay sa mga katangian ng mga materyales na nakabatay sa bakal sa

Narito kami para sa iyong mga katanungan anumang oras 24/7, Maligayang pagdating sa iyong konsultasyon.

Karapatang-ari © 2025 ShenGuang. Lahat ng karapatan ay nakalaan.