Induction heating is a process that uses the principle of electromagnetic induction to heat objects. It is based on Faraday’s law of electromagnetic induction, according to which when a conductor (usually a metal) is placed in a changing magnetic field, an electric current is induced, thereby producing heat.

How induction heat is produced

1. AC power supply: High-frequency AC power supply is usually used to generate changing magnetic fields. This power source generates a high-frequency alternating current through the coil, thereby creating an alternating magnetic field around the coil.

2. Generation of magnetic field: High-frequency alternating current flows in the coil to form an alternating magnetic field. This magnetic field will spread into the surrounding space.

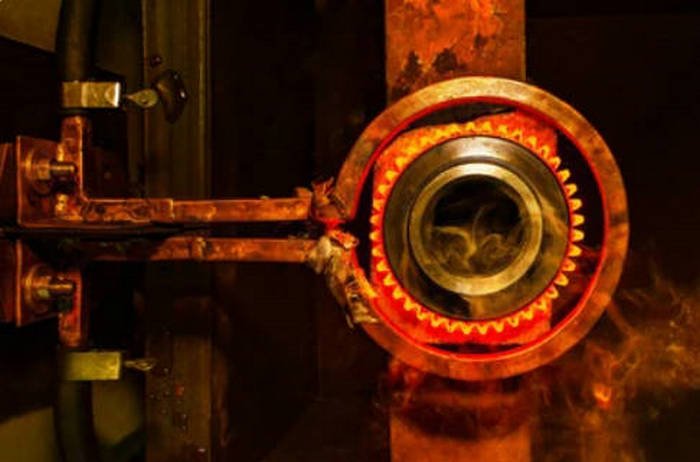

3. Conductor placed in a magnetic field: The object to be heated, usually, a conductor (usually a metal), is placed in this alternating magnetic field. Due to changes in the magnetic field, an electric current is induced inside the object.

4. Induced current generates heat: According to Faraday’s law of electromagnetic induction, when the magnetic flux in the conductor changes, an induced current will be generated. In this case, the magnetic flux is caused by the alternating magnetic field, so the induced current also changes with time. This induced current creates resistance within the conductor, which generates heat. This heat can be used to heat the conductor itself or transferred to other objects in contact with the conductor.

Induction Heating Basics

1. Power supply: Induction heating systems usually use high-frequency AC power to produce high-frequency alternating current.

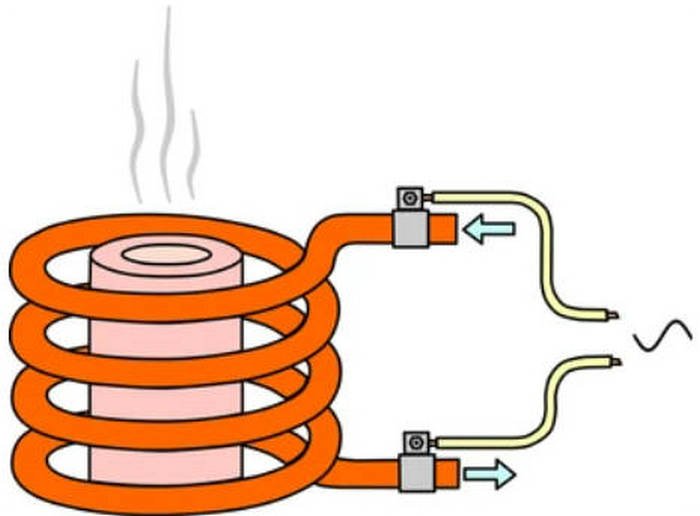

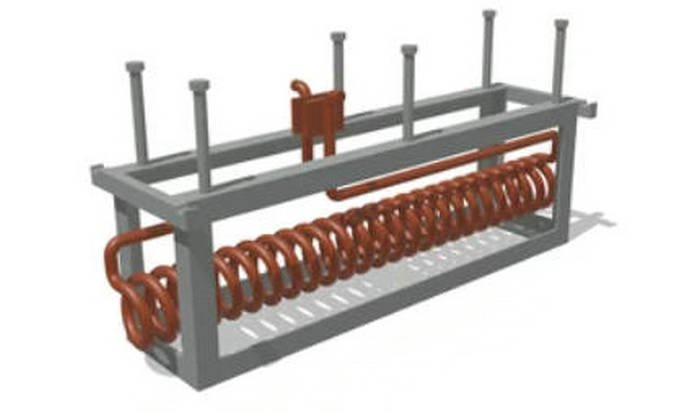

2. Coil: The coil is part of the power supply and is used to generate high-frequency alternating magnetic fields. Coil design and placement are critical to heating effectiveness.

3. Conductor: The object to be heated is usually a conductor, usually a metal. When a conductor is placed in an alternating magnetic field, an induced current is produced.

4. Induced current: The alternating magnetic field causes electrons inside the conductor to move, producing induced current. This induced current creates resistance in the conductor, which generates heat.

5. Hysteresis loss:

Hysteresis losses occur in magnetic materials, such as ferromagnetic materials, when they are placed in an alternating magnetic field. This material undergoes a process of magnetization and demagnetization under the influence of a magnetic field, but this process is not completely reversible. When a magnetic material is periodically magnetized and demagnetized, energy loss occurs between the molecules and the magnetic domains, which is hysteresis loss. This loss causes the material to heat up, so it needs to be considered in applications such as induction heating.

6. Eddy current loss

Eddy current losses occur in conductors when they are exposed to alternating electromagnetic fields. According to Faraday’s law of electromagnetic induction, an alternating magnetic field induces an induced current in a conductor. These induced currents create resistance inside the conductor and generate heat, which is eddy current loss. In induction heating, eddy current losses are often intentionally exploited because it is the primary mechanism used to heat the conductor.

Advantages of induction heating

Induction heating has many advantages and is therefore widely used in a variety of industrial, culinary and other applications.

1. Efficient energy conversion: Induction heating is an efficient heating method. Energy is transferred from the power source to the workpiece with almost no energy wasted, thus enabling higher energy utilization.

2. Rapid heating: Induction heating can heat the workpiece to the required temperature in a very short time. This makes the production process more efficient and reduces waiting times.

3. Precise temperature control: Induction heating enables precise control of the workpiece temperature because heating can be quickly started or stopped as needed. This is important for applications that require tight temperature control, such as heat treating and welding.

4. Uniform heating: The heat generated by induction heating is evenly distributed inside the entire workpiece, so the problem of uneven heat treatment or deformation can be avoided.

5. Non-contact heating: Induction heating is a non-contact heating method because it does not require a heating element in contact with the workpiece, such as a flame or resistance heater. This reduces the risk of material contamination and mechanical damage.

6. Can be automated and integrated: Induction heating can be easily integrated with automated systems, making it suitable for high-volume industrial manufacturing processes. It can be used with robots, conveyors and other automated equipment.

7. Save energy and costs: Due to its high efficiency, induction heating can reduce energy consumption and operating costs, reducing the overall cost of the production process.

8. Environmentally friendly: Induction heating usually does not involve an open flame or combustion process, so it emits less pollutants and is environmentally friendly.

Induction heating is a flexible and efficient heating method suitable for a variety of industrial and non-industrial applications. It offers many advantages including efficient energy utilization, precise temperature control, uniform heating, etc., making it one of the preferred heating technologies in many industries.

Does coil design matter in induction heating systems?

Coil design is very important in induction heating systems because the coil is one of the key components of induction heating, which directly affects heating efficiency, heating uniformity and system performance. The following is the importance of coil design in induction heating systems:

1. Heating efficiency: The design of the coil affects the efficiency of energy transfer. The optimized coil design ensures that as much electromagnetic energy as possible is transferred to the workpiece, thereby improving heating efficiency. Efficient coil design also reduces energy waste and lowers operating costs.

2. Heating uniformity: The shape, size and position of the coil will affect the heating uniformity of the workpiece. Proper coil design ensures uniform temperature distribution inside the workpiece and avoids hot and cold spots. This is important for applications that require precise temperature control, such as heat treatment.

3. Frequency selection: Different coil designs can be used to generate electromagnetic fields of different frequencies. The frequency selection of the coil depends on the material and size of the workpiece, as well as the required heating depth. Appropriate frequency selection helps optimize the heating effect.

4. Coil durability: Coils must be designed to withstand high temperature, high frequency and high current environments. Appropriate coil materials and structural design can ensure stable operation of the coil for a long time and reduce maintenance costs.

5. System integration: Coil design also needs to consider how to integrate with the entire induction heating system. This includes the coil’s cooling system, power connections and control systems, etc. Coils must work in harmony with other components to ensure proper operation of the system.

Overall, coil design is critical to the performance and stability of your induction heating system. Optimized coil design can improve heating efficiency, heating uniformity and system reliability to adapt to different application needs, including industrial production, heat treatment, welding, medical equipment and food heating, etc. Therefore, coil design is often an important consideration in the design and optimization of induction heating systems.

Applications of induction heating

Induction heating is a heating technology widely used in various industrial and non-industrial fields. It transfers energy into conductive materials through the principle of electromagnetic induction, thereby heating objects. Here are some of the main application areas for induction heating:

1. Industrial heating: Induction heating is widely used in industrial production to heat metal and non-metallic materials for various processes, including forging, quenching, heat treatment, crucible melting, brazing, thermal welding, metal hot pressing, etc. It is commonly used to heat parts, bearings, gears, pipes and other industrial components.

2. Medical equipment: In the medical field, induction heating is used to generate high-frequency electromagnetic fields to heat tissues for physical therapy, such as high-frequency hyperthermia and electromagnetic induction heating therapy.

3. Food heating: Induction heating is used in the food industry to quickly heat food and liquids, such as induction heating furnaces and induction heating stoves. This method heats food quickly, improving production efficiency while reducing the risk of overheating and burning the food.

4. Aerospace: Induction heating is used in the aerospace field, including the heating and heat treatment of aircraft engine parts to improve material performance and durability.

5. Automobile Manufacturing: In automobile manufacturing, induction heating is used in a variety of applications, including welding, thermoforming, quenching and surface treatment, to improve the performance and quality of parts.

6. Electronic Manufacturing: Induction heating is used in the manufacture of semiconductor equipment, circuit boards and electronic components in electronic manufacturing to ensure high precision and performance.

7. Metallurgy: In the metallurgical industry, induction heating is used in metal smelting, casting and alloy preparation to obtain the desired metal properties.

8. Home appliances: Induction heating is also used in home appliances, such as induction heating stoves, induction heating kettles and induction heating cookers, to improve cooking efficiency and safety.

In general, induction heating is an efficient, precise and widely applicable heating technology. It has important applications in many fields and helps to increase production efficiency, improve product quality and save energy.

Power requirements

The power requirements of induction heating systems are critical because they directly affect heating efficiency and system performance. The following are the main aspects of power requirements for induction heating systems:

1. High-frequency AC power supply: Induction heating usually requires high-frequency AC power supply, with the frequency usually ranging from thousands of hertz (Hz) to hundreds of kilohertz. This is because high-frequency AC power effectively induces currents in conductors, thereby generating heat.

2. Power requirements: The power requirements of the power supply depend on the application of the induction heating system and the size of the workpiece. Large industrial induction heating systems may require thousands of kilowatts (kW) or even megawatts (MW) of power, while small household induction heating equipment typically requires only a few hundred watts (W) to several kilowatts of power.

3. Stability and controllability: The power supply must provide stable current and voltage to ensure control and stability of the heating process. Induction heating systems often require highly precise current and voltage control.

4. Frequency adjustability: Some applications require the ability to adjust the operating frequency of the power supply to adapt to the requirements of different materials and workpiece sizes. Therefore, some induction heating system power supplies have adjustable frequency capabilities.

5. Power supply efficiency: An efficient power supply can reduce energy waste and reduce operating costs. The efficiency of a power supply is usually measured in terms of power factor and conversion efficiency.

6. Safety: The power supply must comply with safety standards to ensure the safety of operators. This includes features such as overcurrent protection, overvoltage protection, and temperature protection.

7. Adaptability: The power supply must adapt to the heating requirements of different materials and workpieces. Therefore, it may need to have multiple power and frequency settings to suit different heating applications.

8. Control system integration: The power supply usually needs to be integrated with the control system of the induction heating system to realize automation and monitoring of the heating process.

In summary, the power requirements for induction heating systems vary based on specific application needs and workpiece characteristics. These requirements need to be carefully considered when designing and selecting a power supply to ensure that the system can operate stably and efficiently to meet the requirements of the heating process.