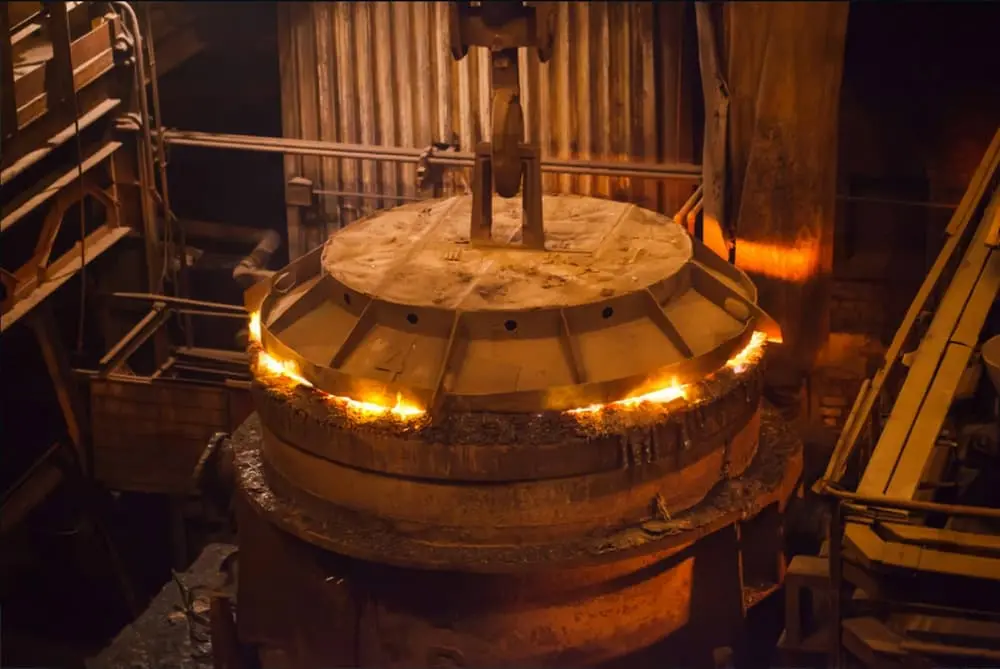

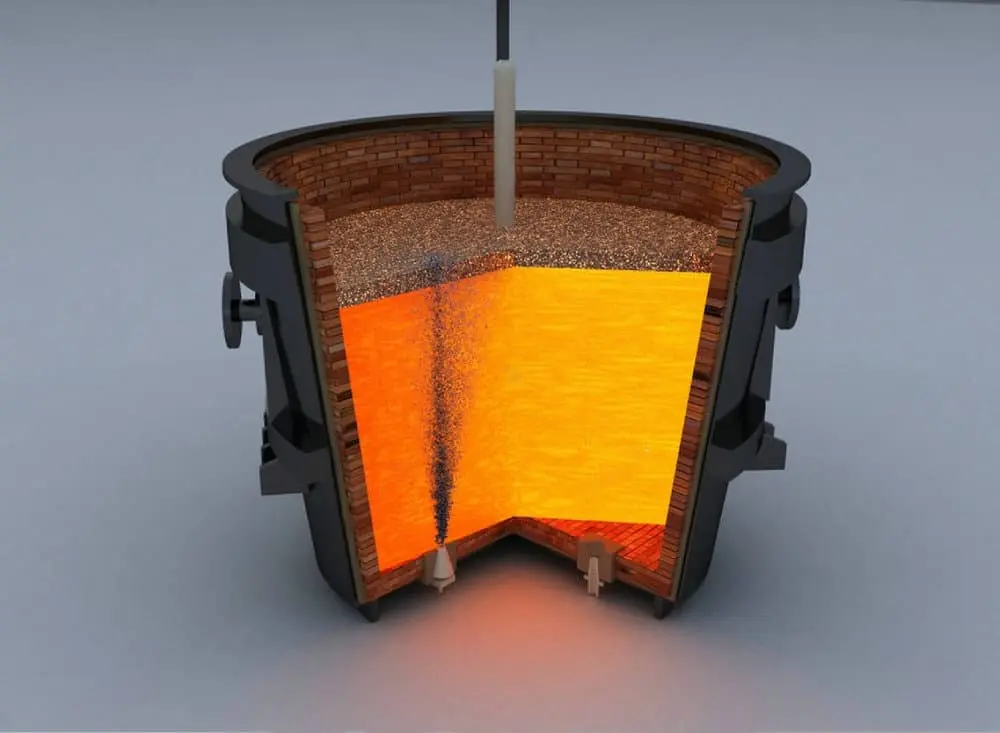

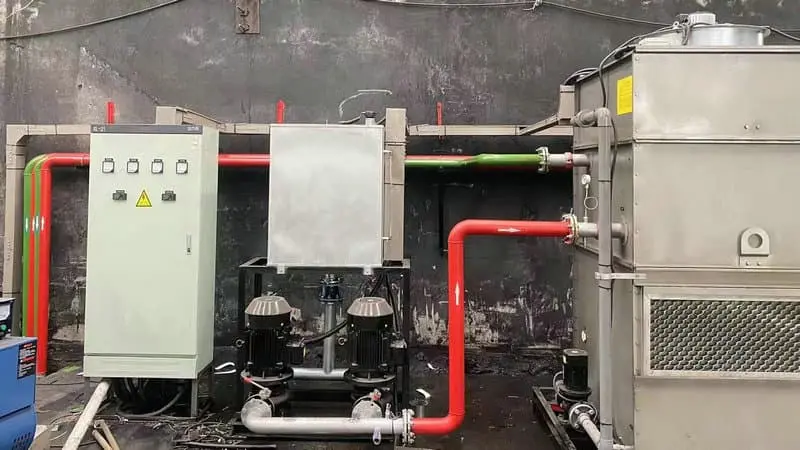

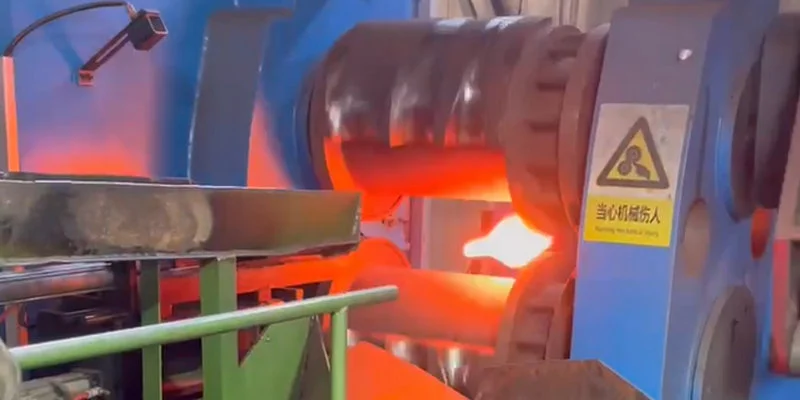

How to strengthen equipment management of small medium frequency furnace enterprises and reduce harmonic pollution to the power grid

Strengthening equipment management in small and medium-sized frequency furnace enterprises and reducing harmonic pollution to