Induction Melting Furnaces

Classification by Capacity

We are professional induction furnace manufacturer, customized medium frequency induction furnace, the capacity of our machines ranges from 50kg to 90 tons.

Classification by Metal

The products of Shenguan Electric Furnace Company have a wide range of uses. The induction furnace is suitable for melting or heating stainless steel, cast steel, cast iron, copper, aluminum, zinc, magnesium, chromium, silver, neodymium iron boron, amorphous alloy and other metal materials and their alloys.

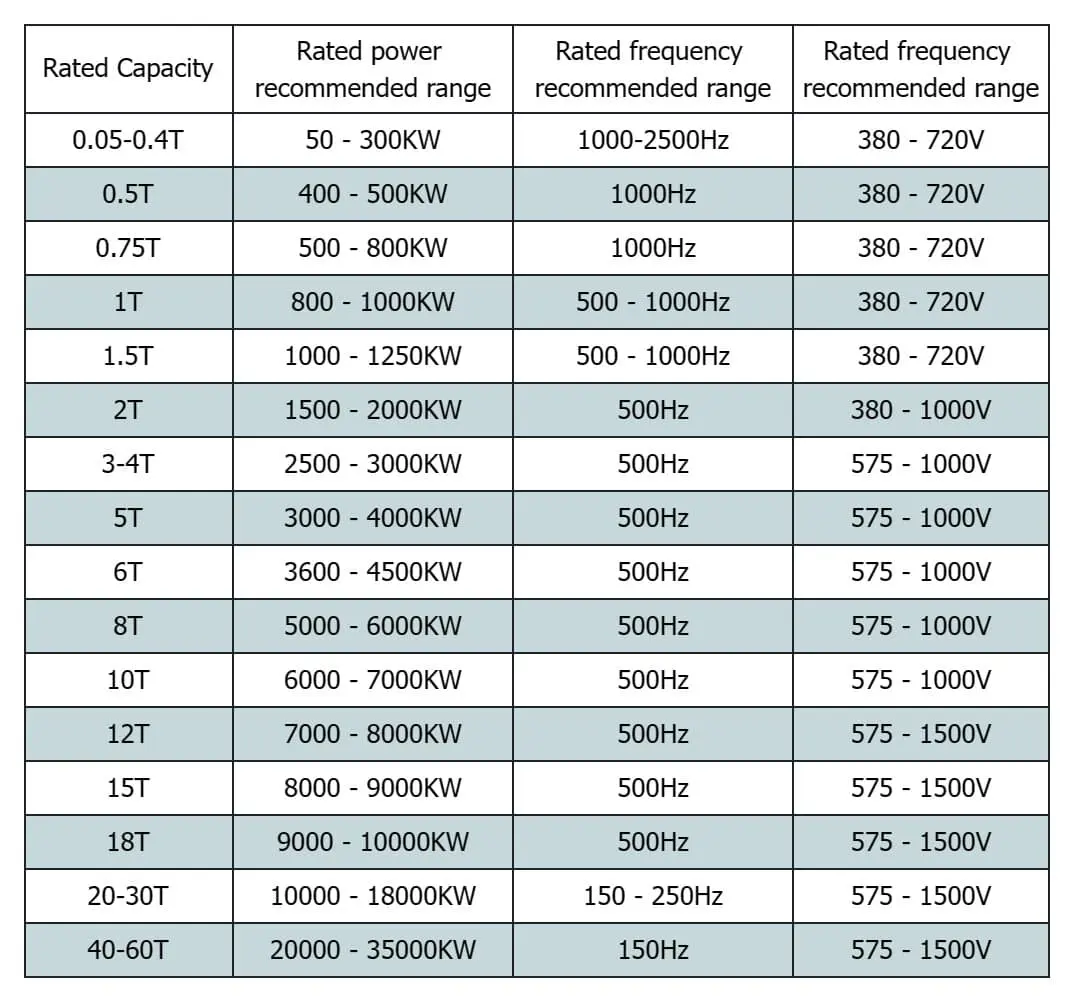

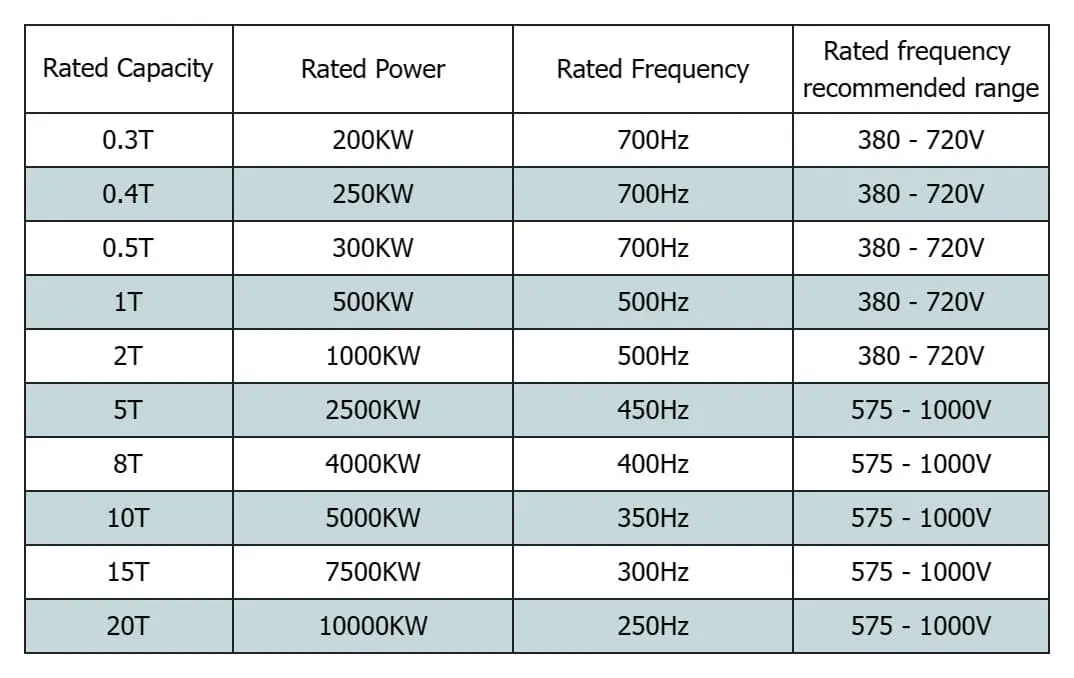

Melting Furnace Technical Parameters

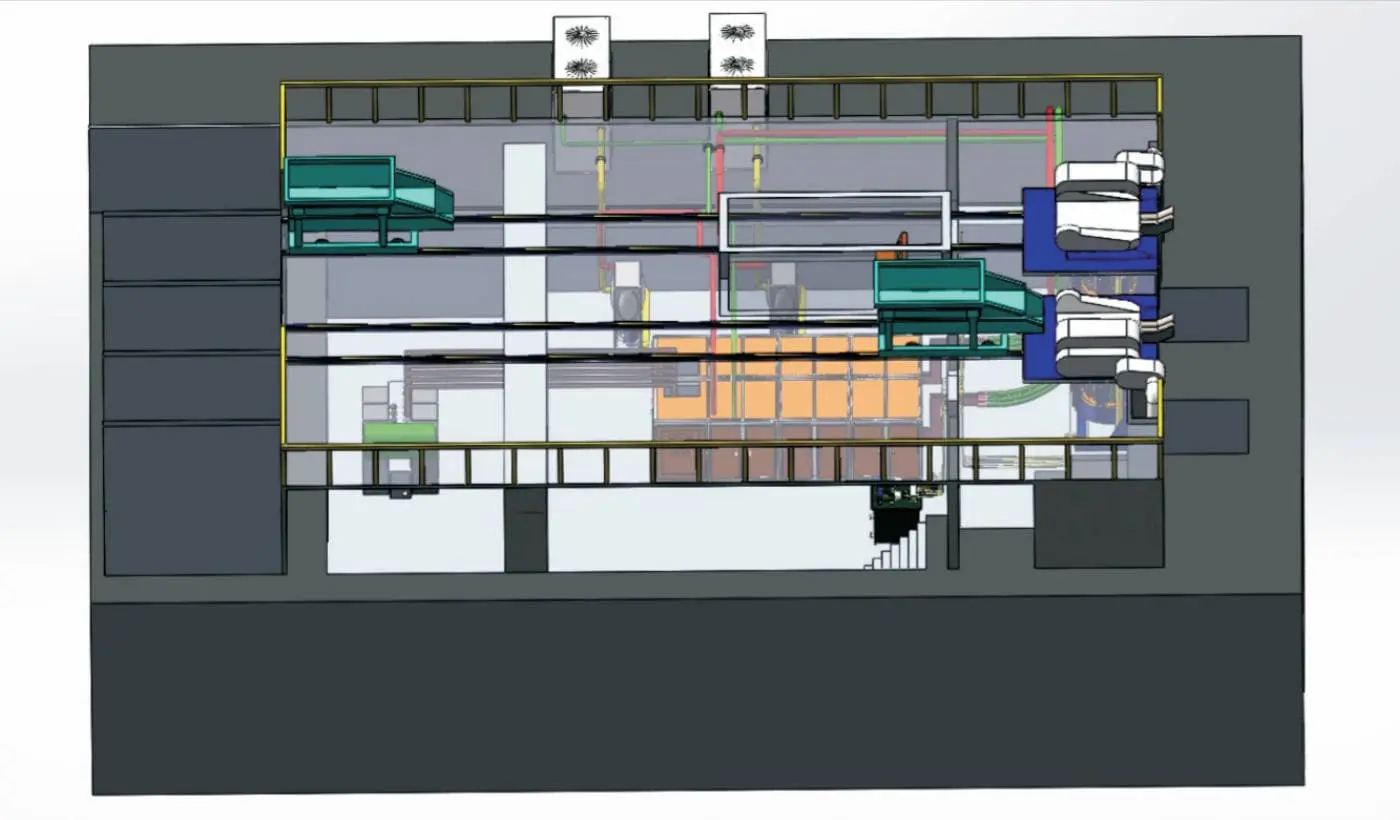

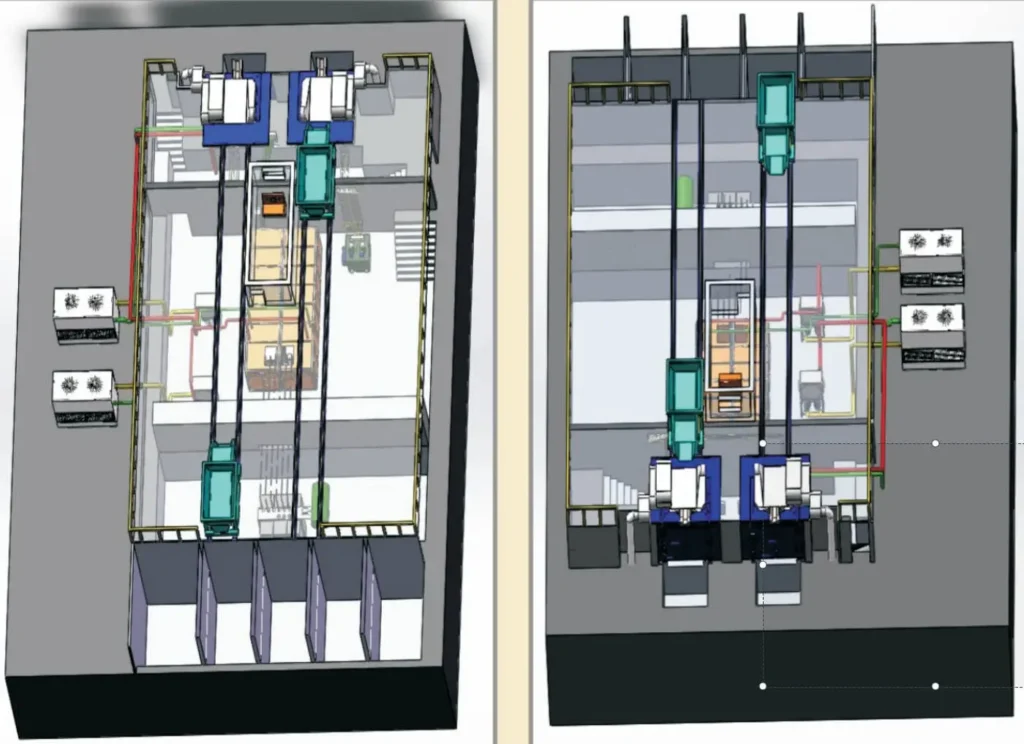

The VIP series inverter medium frequency electric furnaces produced by our company (one to one, one to two, one to three, etc.) adopt the latest international technology, with power from 100 to 3000KW and furnace capacity from 0.05 to 60 tons. The energy saving rate of this product can reach 15% to 20%, and it is widely used in heating, diathermy, quenching, vacuum furnace smelting, etc.

The incoming line voltage of the fast energy-saving medium frequency power supply produced by our company is 380V to 1250V, which is divided into 6 pulses, 12 pulses and 24 pulses, the power is 30KW to 30000KW, and the electric furnace capacity is 0.05 tons to 60 tons.

The power supply power of energy-saving power frequency electric furnaces and power frequency holding furnaces is 45KW to 600KW, and the capacity of the electric furnaces is 150kg to 3000kg. They adopt two-phase and three-phase high and low voltage balancing devices to produce magnesium alloy and aluminum alloy die-casting melting furnaces.