Understanding the Working Principle of a Closed Cooling Tower

A closed cooling tower is a crucial piece of equipment in industrial settings, responsible for

A closed cooling tower is a crucial piece of equipment in industrial settings, responsible for

There are notable differences between the neutral and acidic linings of intermediate frequency (IF) furnaces,

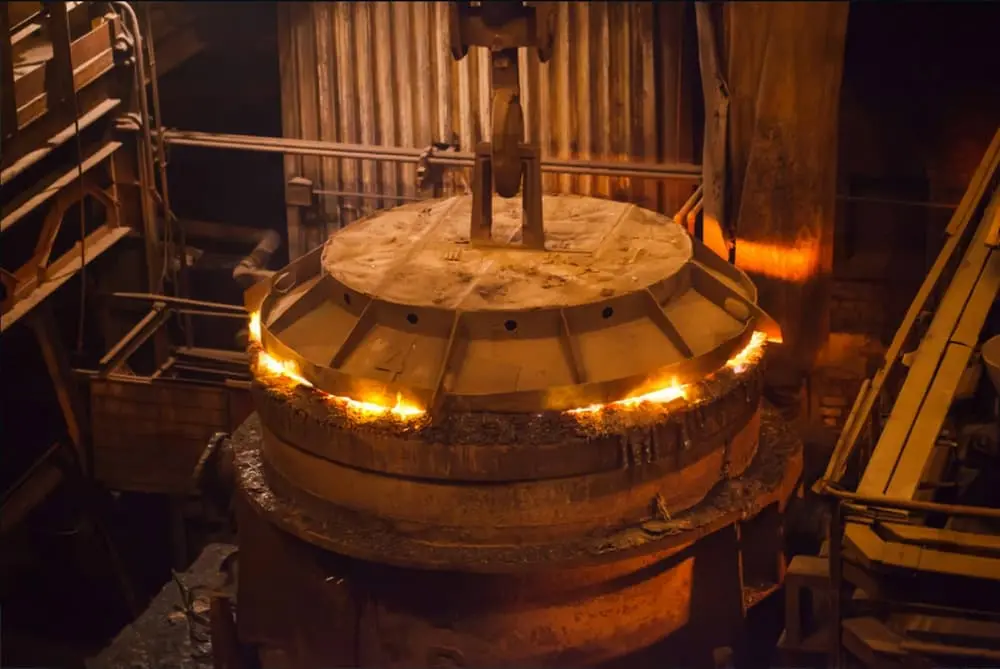

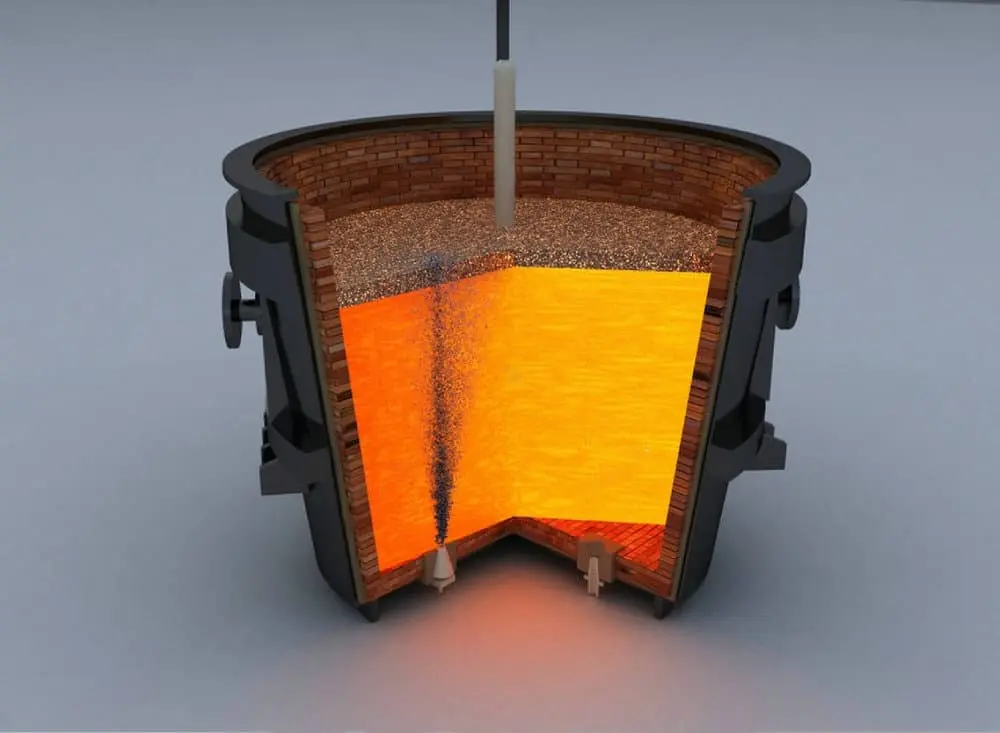

A smelting furnace is a specialized furnace used for melting various ores, primarily iron ore,

Different types of copper and its alloys have different melting points. Pure copper melts at

Copper ingots, as an important metal material, play an important role in the electrical industry,

Preheating Method Precautions By adhering to these preheating methods and precautions, you can ensure the

In the field of metal processing, aluminum is widely used due to its excellent electrical

The transformer is vital to the operation of intermediate frequency (IF) furnaces, with its stability

Subcutaneous pores in castings are a common defect, requiring a series of preventive and corrective

Spheroidization decline is a common issue in ductile iron production, often leading to substandard castings

Poor spheroidization is a common challenge in casting, significantly impacting the performance and quality of

Graphite flotation in castings can significantly impact both the mechanical properties and the appearance of

When it comes to working with metals, brass stands out for its versatility and beauty.

Introduction to Metal Melting Furnaces What is a Metal Melting Furnace? A metal melting furnace

Introduction to Cast Iron Melting Furnaces Cast iron melting furnaces are essential tools in metalworking,

Induction furnaces are increasingly vital in zinc smelting due to their efficiency and environmental benefits.

Strengthening equipment management in small and medium-sized frequency furnace enterprises and reducing harmonic pollution to

The most efficient metal melting furnace can depend on several factors, including the type of

To calculate the energy required to melt 1 ton of aluminum, we need to consider

When performing medium-frequency induction furnace smelting operations, the following six conditions must be strictly adhered

Melting aluminum requires careful handling and proper equipment due to its high melting point and

Melting zinc in an induction furnace is a process used in various industries for applications

The various processes in the use of the medium frequency furnace are also very important

We are excited to announce that Ningbo Shenguang Electric Furnace Co., Ltd. will be participating

Things you need to know about induction furnace for copper melting. 1. How Induction Furnaces

When considering the use of an induction furnace for steel melting, there are several important

The history and importance of copper Copper, as an ancient and precious metal, was discovered

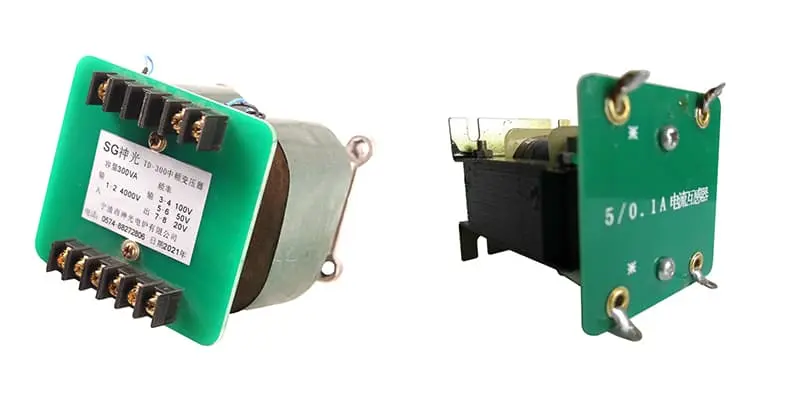

KGPS Technology Working principle Control circuit principle The entire control circuit, except for the inverter’s

Heat treatment is a crucial process in materials science, primarily used to alter the physical

What is induction melting equipment? Induction melting equipment is a type of technology used to

Melting gold is a process that requires specific equipment and safety measures due to the

Understanding Silver’s Properties Safety Precautions Equipment Needed Melting Process Cooling and Handling Post-Melting Processing Additional

Induction furnaces and electric arc furnaces are both used for melting metals, but they operate

Choosing the right induction furnace manufacturer is crucial for ensuring that your investment meets your

Four methods of heating metal with electrical energy Resistance heating Resistance heating is a method

Melting and smelting are processes that involve the transformation of substances from one state to

The Current transformer is an instrument that works based on the principle of electromagnetic induction.

Copper plays a dual role in steel production, serving both as a beneficial alloying element

The full name of IGBT is Insulated Gate Bipolar Transistor.It is a composite fully controlled

Chromium is the most widely used and most commonly used alloy element. Chromium has a

According to the main matrix elements of the alloy, high-temperature alloys can be mainly divided

What is bottom slag? Bottom slag refers to the slag that is deliberately placed at

Crucible materials for induction furnace smelting should meet the following requirements. 1. The crucible material

Nickel and cobalt are elements with similar physical and chemical properties. They are alloy elements

Induction melting furnaces are mainly divided into two types: cored and coreless. Among them, coreless

Induction furnaces are heating devices widely used in industrial production. Its working principle is based

Furnace Construction Tools Pre-furnace Preparation Work Before furnace construction, thorough preparation is essential. This includes:

Based on Power Frequency: 1. Medium frequency furnace The power frequency range of the medium

Working principle and heating method Medium frequency electric furnace: The induced current generated by electromagnetic

Deoxidation Effect of Carbon in Vacuum In a vacuum environment, carbon demonstrates remarkable deoxidation capability,

Melting nickel-based alloys in intermediate frequency furnaces demands meticulous attention to prevent common issues such

The metallic and non-metallic raw materials involved in induction furnace smelting are broadly classified into

How to take correct measures to improve the quality level of mold steel during medium

Thyristor intermediate frequency (IF) power supply is a crucial static frequency conversion device leveraging thyristor

The role of furnace lining in induction metal melting furnace The furnace lining in an

When a steel plant smelting aluminum, the choice between an electric induction melting furnace or

Use Industrial Pure Iron for Cleaning and Maintenance: Cleaning the induction crucible with industrial pure

Application of intermittent melting principle in intermediate frequency furnace At the beginning of smelting in

Discover effective methods for accurately measuring metal melting temperatures with this comprehensive guide. Learn the

Importance of Scrap Metal Recycling: What are the sources of steel scrap from steel mills?

We are here for your questions anytime 24/7, welcome your consultation.

Copyright © 2025 ShenGuang. All rights reserved.